Imagine having a powerful tool that allows you to effortlessly drill precise holes with ease. In this article, we will explore the fascinating world of column drills and discover their unique features. Are you curious about the characteristics of a column drill and how it can revolutionize your drilling experience? Well, get ready to be amazed as we uncover the secrets behind this indispensable tool. So, fasten your seatbelts and let’s embark on a journey to explore the incredible features of the column drill.

Power

Motor power

The motor power of a column drill is an important factor to consider when choosing a drill. A higher motor power allows the drill to handle tougher materials and perform heavy-duty drilling tasks with ease. It provides the necessary torque to drill through materials like metal, wood, and concrete. A column drill with a powerful motor will be able to drill faster and more efficiently, reducing the drilling time and increasing productivity.

Speed control

The speed control feature in a column drill allows you to adjust the rotational speed of the drill bit according to the material being drilled. Different materials require different drilling speeds for optimal results. For example, drilling through metal requires a slower speed to prevent overheating and to maintain accuracy, while drilling through wood can be done at a higher speed. A column drill with variable speed control gives you the flexibility to choose the right speed for each drilling task, ensuring precise and efficient drilling.

Working voltage

The working voltage of a column drill determines its power source and electrical requirements. Most column drills operate on standard household voltage, typically 110-120V or 220-240V. It is essential to check the voltage compatibility of the drill with the available power supply in your workshop or location. Using the correct working voltage is crucial for the safety and proper functioning of the drill. Additionally, some column drills have the option to run on both AC and DC power, providing versatility and convenience for different work environments.

Size and Weight

Dimensions

The dimensions of a column drill are an essential consideration, especially if you have limited space in your workshop or need to transport the drill to different locations. The height, width, and depth of the drill will determine its footprint and how it fits into your workspace. Compact column drills are ideal for small workshops or hobbyists who need a portable drilling solution. On the other hand, larger column drills with a bigger working table may be required for industrial or heavy-duty applications. It is important to measure your available space and consider the size of the drill before making a purchase.

Weight

The weight of a column drill can affect its portability and stability. A lightweight drill is easier to transport and maneuver, making it convenient for on-site projects or moving around a workshop. However, it is important to ensure that the drill is stable during operation, even if it is lightweight. Heavier column drills with a sturdy construction provide better stability and reduce vibrations, ensuring precise drilling and minimizing the risk of accidents. Consider the intended use of the drill and choose a weight that balances portability and stability based on your specific needs.

Construction and Design

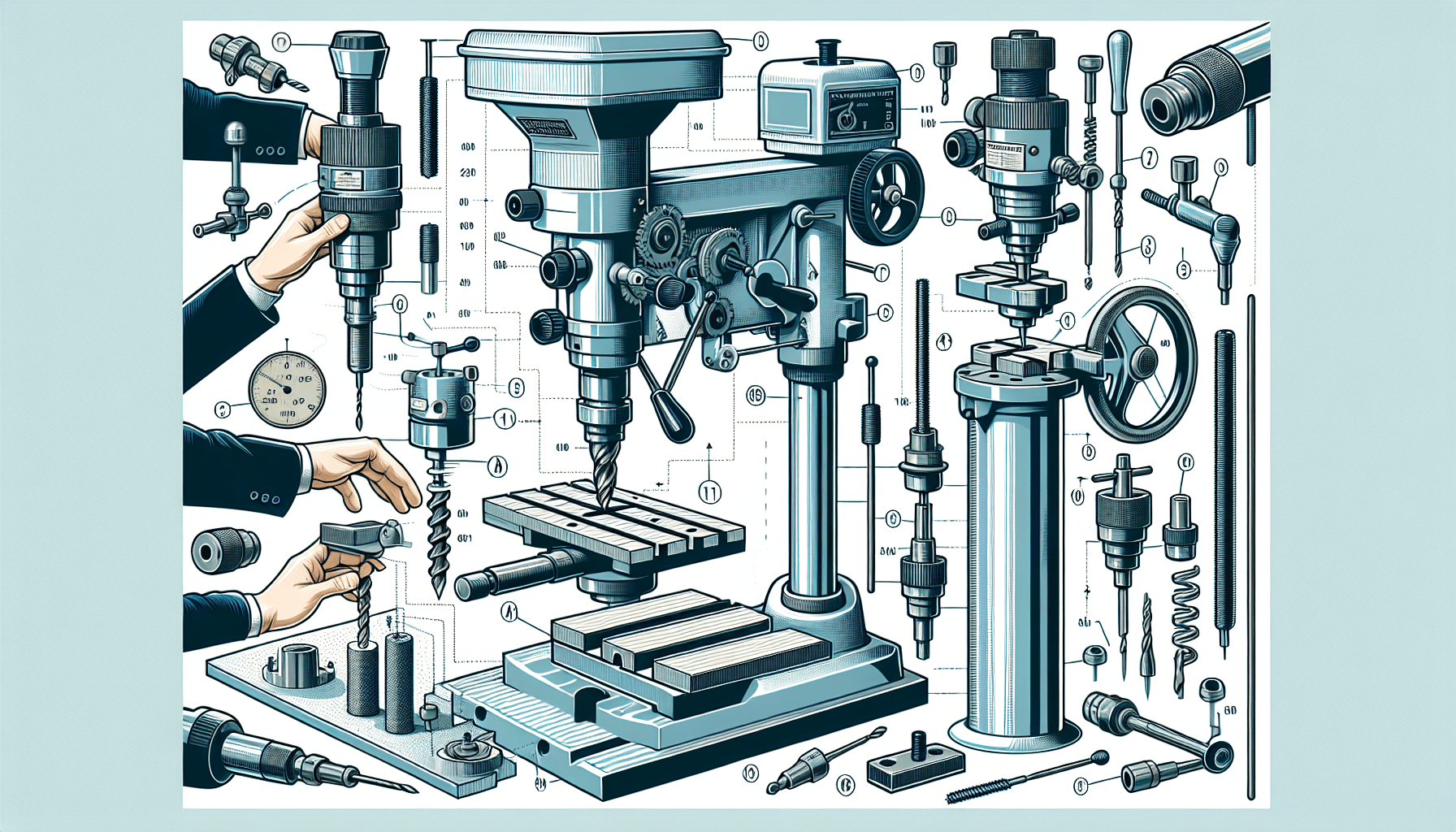

Column

The column of a column drill is the vertical structure that houses the motor, quill, and other critical components. It provides stability and support during operation, preventing unnecessary vibrations and wobbling. A robust and well-built column ensures precise drilling and improves the overall durability of the drill. Look for a column made from high-quality materials like cast iron or steel for maximum strength and stability.

Base

The base of a column drill supports the entire weight of the drill and provides stability during operation. A wide and heavy-duty base reduces the risk of tipping or wobbling, ensuring safe and accurate drilling. Look for a column drill with a sturdy base that can be securely bolted to the floor or workbench for added stability, especially when working with larger or heavier workpieces.

Table

The table of a column drill is the working surface where the material to be drilled is placed. It should be flat, level, and sturdy to provide stability and accuracy during drilling. An adjustable table allows the user to tilt, swivel, and raise or lower the work surface to accommodate different drilling angles and heights. Look for a column drill with a spacious and versatile table that can be easily adjusted to suit your drilling needs.

Chuck

The chuck is the component that holds the drill bit securely in place and allows for easy bit changes. A high-quality chuck ensures accurate and reliable drilling. Keyed chucks require a chuck key to tighten and loosen the drill bit, providing extra security during drilling. Keyless chucks, on the other hand, allow for quick and tool-free bit changes, saving time and effort. Consider the type of chuck that best suits your needs and ensures a secure grip on the drill bit.

Quill

The quill is the part of the column drill that holds and moves the drill bit up and down during drilling. It is important to have smooth and precise quill movement to ensure accurate drilling depth control. Look for a column drill with a quill that operates smoothly and has minimal play or wobble. A quill with adjustable depth control settings allows for precise drilling at different depths.

Spindle

The spindle of a column drill is the component that holds the chuck and rotates the drill bit. It is responsible for the drilling action and determines the maximum drill capacity of the drill. The spindle should be sturdy and well-designed to handle the drilling forces and vibrations. Look for a column drill with a robust spindle that can accommodate a wide range of drill bit sizes and provide smooth and reliable drilling action.

Versatility

Drill capacity

The drill capacity refers to the maximum diameter of the hole that can be drilled with a column drill. It is an important consideration when choosing a drill, especially if you work with different-sized drill bits and need versatility in your drilling tasks. A column drill with a larger drill capacity allows you to tackle a wider range of projects and drill holes of various sizes. Consider the maximum drill capacity of the drill and ensure it meets your specific drilling requirements.

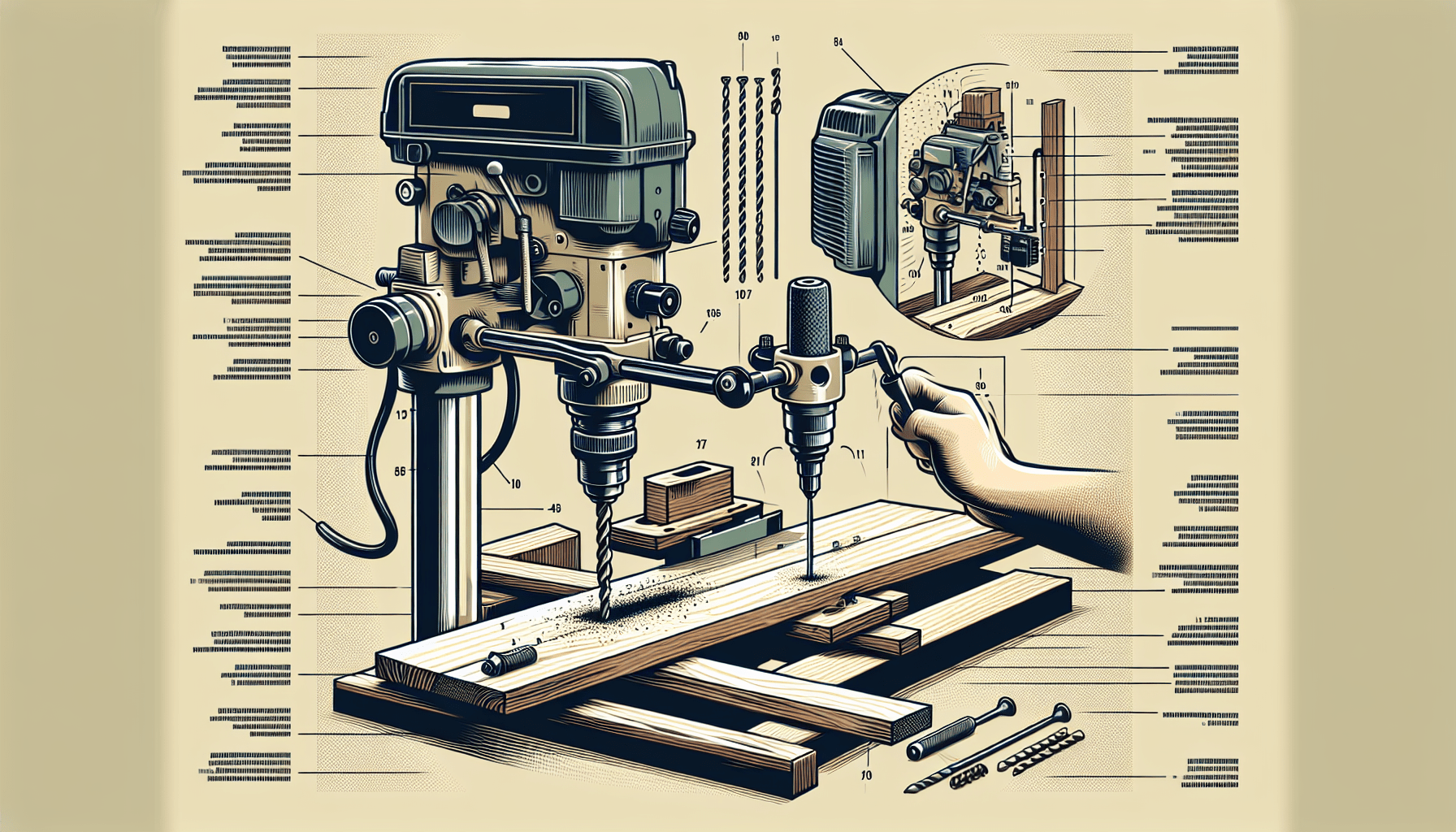

Adjustable table

An adjustable table provides versatility in drilling angles and heights, allowing you to adapt to different workpieces and drilling requirements. Look for a column drill with a table that can be tilted, swiveled, and raised or lowered to accommodate various drilling positions. This feature is particularly useful when drilling angled holes or working with irregularly shaped materials. The ability to adjust the table enhances the versatility of the drill, enabling you to tackle a wide range of drilling tasks with ease.

Multiple speed settings

Having multiple speed settings in a column drill allows you to adjust the rotational speed of the drill bit according to the material being drilled. Different materials require different drilling speeds for optimal results. For example, drilling through metal requires a slower speed to prevent overheating and maintain accuracy, while drilling through wood can be done at a higher speed. Look for a column drill with variable speed settings to ensure flexibility and precision in your drilling tasks.

Compatibility with different materials

A versatile column drill is capable of drilling through a variety of materials, including wood, metal, plastic, and concrete. It should have the necessary power and speed control to handle different drilling requirements. Look for a column drill with compatible drill bits and accessories that are specifically designed for different materials. This ensures efficient and precise drilling, regardless of the material you are working with. Consider the range of materials you work with and choose a column drill that offers the necessary compatibility.

Stability and Precision

Column stability

The stability of the column is crucial for accurate and safe drilling. A well-built and stable column reduces vibrations and wobbling during operation, ensuring precise drilling and minimizing the risk of accidents. Look for a column drill with a sturdy and robust column that can withstand the drilling forces and provide a stable platform for drilling.

Quill movement

The movement of the quill should be smooth and precise for accurate depth control during drilling. Excessive play or wobble in the quill can result in inconsistent drilling depths and affect the overall precision of the drill. Look for a drill with a quill that operates smoothly and has minimal play or wobble. This ensures precise drilling at different depths and enhances the overall precision of the drill.

Chuck accuracy

The accuracy of the chuck is essential for maintaining the alignment and stability of the drill bit during drilling. A high-quality chuck ensures a secure grip on the drill bit, preventing slippage and reducing the risk of accidents. Look for a drill with a chuck that operates smoothly and securely holds the drill bit in place. This improves accuracy and precision during drilling, resulting in clean and precise holes.

Depth control

The ability to control the drilling depth is important, especially when drilling holes to specific measurements or when working with different materials. Look for a column drill with adjustable depth control settings that allow for precise drilling at different depths. This ensures consistent and accurate drilling results, making the drill suitable for a wide range of projects and applications.

Safety Features

Emergency stop button

An emergency stop button is an important safety feature in a column drill. It allows you to quickly halt the drilling operation in case of emergencies or accidents. Look for a column drill with an easily accessible and clearly labeled emergency stop button. This ensures immediate response and enhances the overall safety of the drill.

Safety guard

A safety guard is designed to protect the operator from flying debris, especially when drilling materials like metal or wood. It is typically attached to the column or table of the drill and deflects debris away from the operator. Look for a column drill with a sturdy and effective safety guard that provides maximum protection during drilling operations.

Chuck key guard

A chuck key guard is a safety feature that prevents accidental activation of the drill when the chuck key is left inside the chuck. It ensures that the chuck key is removed before the drill is turned on, reducing the risk of injuries or damage. Look for a column drill with a chuck key guard that securely holds the chuck key and prevents it from engaging the drill.

Overload protection

Overload protection is a safety feature that protects the motor and other components of the column drill from excessive heat or damage caused by overload. It automatically shuts off the drill or reduces the speed to prevent overheating or burning out the motor. Look for a column drill with overload protection to ensure the longevity and safety of the drill, especially when working on demanding or heavy-duty projects.

Ease of Use

User-friendly controls

User-friendly controls make operating the column drill easy and intuitive. Look for a drill with clearly labeled and easily accessible controls that allow you to adjust speed, depth, and other settings effortlessly. This simplifies the setup process and ensures smooth and efficient drilling operations.

Quick tool changes

A column drill that allows for quick and easy tool changes saves time and effort. Look for a drill with a keyless chuck or a chuck that requires minimal tool changes. This allows you to switch between drill bits or other accessories quickly, enhancing productivity and efficiency.

Easy setup

An easy setup process reduces downtime and ensures that the drill is ready for use in a short amount of time. Look for a column drill with clear instructions and a straightforward assembly process. This allows you to set up the drill quickly and start drilling without unnecessary delays.

Convenient accessories

Having convenient accessories included with the column drill enhances its usability and versatility. Look for a drill that comes with a variety of drill bits, clamps, and other accessories that are commonly used in drilling operations. This saves you from having to purchase additional accessories separately and ensures that you have everything you need to start drilling.

Durability

Quality materials

The use of high-quality materials in the construction of a column drill ensures its durability and longevity. Look for a drill made from robust materials like cast iron or steel that can withstand the rigors of drilling. High-quality materials also contribute to the stability and accuracy of the drill, providing reliable performance over an extended period.

Robust construction

A column drill with a robust construction is more likely to withstand heavy-duty drilling tasks and other demanding applications. Look for a drill with a solid and well-built structure, reinforced joints, and durable components. This ensures that the drill can handle the drilling forces and vibrations without compromising its performance or structural integrity.

Longevity

Investing in a column drill that has a reputation for longevity can save you money in the long run. Look for a drill from reputable brands with a proven track record for producing durable and reliable products. Consider reading reviews and testimonials from other users to gauge the longevity and performance of the drill over time.

Maintenance

Cleaning

Regular cleaning is essential to keep the column drill in optimal condition. Remove any debris, dust, or shavings that may accumulate around the chuck, table, and other components. Use a soft brush or air compressor to clean hard-to-reach areas, ensuring that the drill operates smoothly and efficiently.

Lubrication

Lubrication is necessary to maintain the smooth operation of the column drill. Apply lubricating oil or grease to the moving parts like the quill, spindle, and gears. This reduces friction, prevents premature wear, and extends the lifespan of the drill. Follow the manufacturer’s recommendations on the type of lubricant to use and the frequency of lubrication.

Regular check-ups

Regular check-ups and inspections help identify any potential issues or wear and tear in the column drill. Check for loose or worn-out components, damaged cords, or any signs of malfunction. Addressing these issues promptly can prevent further damage and ensure the safety and performance of the drill. It is also recommended to have the drill serviced by a professional technician at regular intervals to keep it in optimal condition.

Price and Brand

Affordability

Price is an important consideration when buying a column drill. Set a budget and consider the features and specifications that are essential for your specific drilling needs. While it is tempting to opt for the cheapest drill, quality and durability should not be compromised. Look for a column drill that offers a good balance between affordability and quality, ensuring that you get value for your money.

Reputable brands

Choosing a column drill from a reputable brand gives you confidence in the quality and performance of the product. Well-established brands often have a history of producing reliable and durable tools. They also offer better customer support, warranty options, and service centers. Consider researching reputable brands and reading reviews to ensure that you choose a column drill from a trusted manufacturer.