In this article, we will explore the fascinating world of the taladro de columna, also known as a column drill. Have you ever wondered about the inner workings of this versatile tool? Delve into its functionality and discover the various ways it can assist you in your DIY projects or professional endeavors. From its powerful motor to the adjustable height and precision drilling capabilities, the taladro de columna provides a reliable and efficient solution for all your drilling needs. Let’s embark on a journey of exploration and uncover the secrets behind this indispensable tool!

Overview of Column Drill

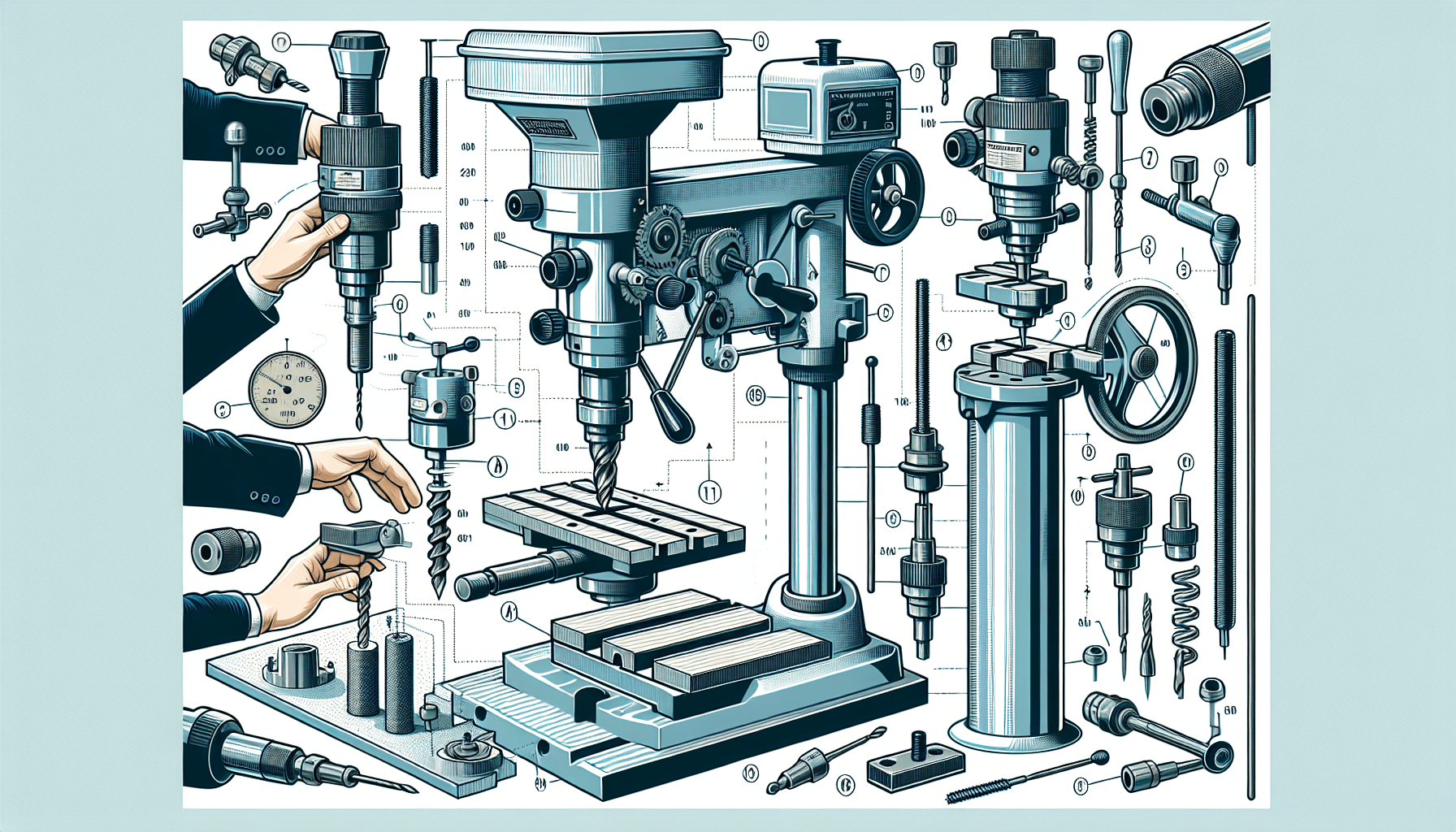

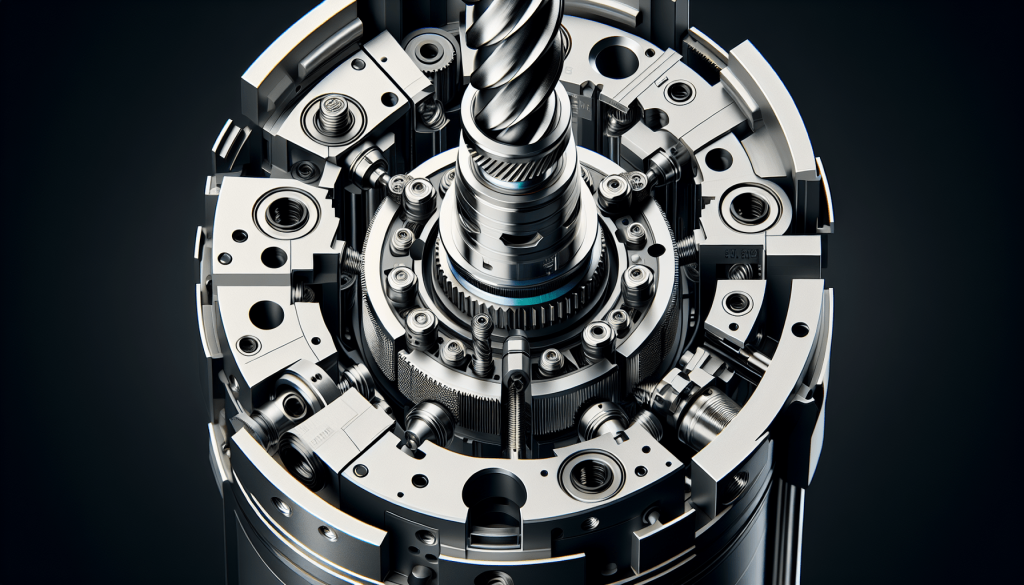

A column drill, also known as a drill press, is a power tool used to accurately drill holes in various materials such as wood, metal, and plastic. It consists of several components that work together to provide stability, control, and power during drilling operations. Understanding the different parts and features of a column drill is essential for ensuring safe and efficient use of this tool.

Definition of Column Drill

A column drill is a stationary power tool that uses a rotating drill bit to create cylindrical holes in materials. It features a vertical column that supports the drilling mechanism, a motor that provides the rotational power, and a table that holds the workpiece in place. This type of drill offers more precision and control compared to handheld drills, making it suitable for tasks that require accuracy and repeatability.

Components of a Column Drill

A column drill consists of several key components that contribute to its functionality and performance. These components include the power source, drilling mechanism, speed and control features, safety features, drill bit compatibility, and more. Understanding each component and its role is crucial for operating a column drill effectively.

Power Source

A column drill can be powered by electricity or be a benchtop or floor-standing model.

Electric Column Drills

Electric column drills are the most common type and are powered by electricity. They are equipped with an electric motor that provides the necessary power for the drilling operation. These drills are convenient to use as they do not require manual effort to generate the drilling force.

Benchtop Column Drills

Benchtop column drills are compact and designed to be placed on a workbench or table. They are ideal for small-scale projects and limited workspace. Despite their smaller size, benchtop drills can still deliver sufficient power for most drilling tasks.

Floor-standing Column Drills

Floor-standing column drills are larger and more robust, designed for heavy-duty drilling operations. They are typically used in professional settings or workshops where large-scale drilling tasks are common. These drills offer greater stability and can handle larger workpieces.

Drilling Mechanism

The drilling mechanism of a column drill consists of various parts that facilitate the drilling process.

Spindle and Chuck

The spindle is the part that holds the drill bit and allows it to rotate. It is attached to the motor and transmits the rotational power to the drill bit. The chuck, on the other hand, is responsible for securing the drill bit in place. It typically has a key or keyless design, allowing for quick and easy changes of drill bits.

Feed Handle and Depth Stop

The feed handle is used to lower or raise the drill bit into the material being drilled. It provides control and precision during the drilling process. The depth stop is a feature that allows you to set the drilling depth, ensuring consistent hole depths across multiple workpieces.

Table and Adjustable Height

The drill table is a flat surface where the workpiece is placed during drilling. It can be tilted or rotated to accommodate angled drilling. Additionally, many column drills feature an adjustable table height, allowing you to position the workpiece at a comfortable level for drilling.

Speed and Control

Speed and control features are essential for achieving accurate and clean drill holes.

Variable Speed Control

Many column drills offer variable speed control, allowing you to adjust the rotational speed of the drill bit. This feature is particularly useful when drilling different materials or using various drill bit sizes. Slower speeds are generally preferred for drilling metal, while faster speeds are suitable for wood and plastic.

Pulley System

The pulley system is responsible for controlling the speed ranges available on a column drill. By changing the belt’s position on the pulleys, you can select different speed settings. Most column drills provide a range of speed options to accommodate various drilling requirements.

Speed Ranges

Different speed ranges are available on column drills, typically categorized as low, medium, and high speeds. Low-speed ranges are ideal for drilling larger holes or using larger drill bits, while high speeds are suitable for smaller holes and drill bits. The middle speed range provides versatility for general drilling tasks.

Safety Features

Safety features are essential to ensure the well-being of the user and prevent accidents.

Safety Guard

A safety guard is a protective barrier that encloses the rotating drill bit. It prevents accidental contact with the drill bit and reduces the risk of injuries. It is crucial to ensure that the safety guard is properly installed and remains in place during operation.

Emergency Stop

Column drills are equipped with an emergency stop button or switch that immediately halts the drilling process when activated. This feature provides a quick and easy way to stop the drill in case of an emergency or any unforeseen hazards.

Chuck Key Safety

Column drills that use a chuck key to secure drill bits often have a safety mechanism to prevent accidental startup. The chuck key must be removed before starting the drill, ensuring that the user is not at risk of injury from a spinning drill bit.

Choosing the Right Drill Bit

Choosing the right drill bit is crucial for achieving desired results and prolonging the lifespan of the drill.

Types of Drill Bits

There are various types of drill bits available for different purposes. Twist drill bits are the most common and suitable for drilling holes in metal, wood, and plastic. For more specialized tasks, there are specific drill bits such as spade bits for large holes in wood or masonry bits for concrete and brick.

Compatibility with Drill Size

It is important to select drill bits that are compatible with the drill size and chuck capacity. Using bits that are too large or too small can lead to inefficiency, inadequate performance, and potential damage to the drilling mechanism.

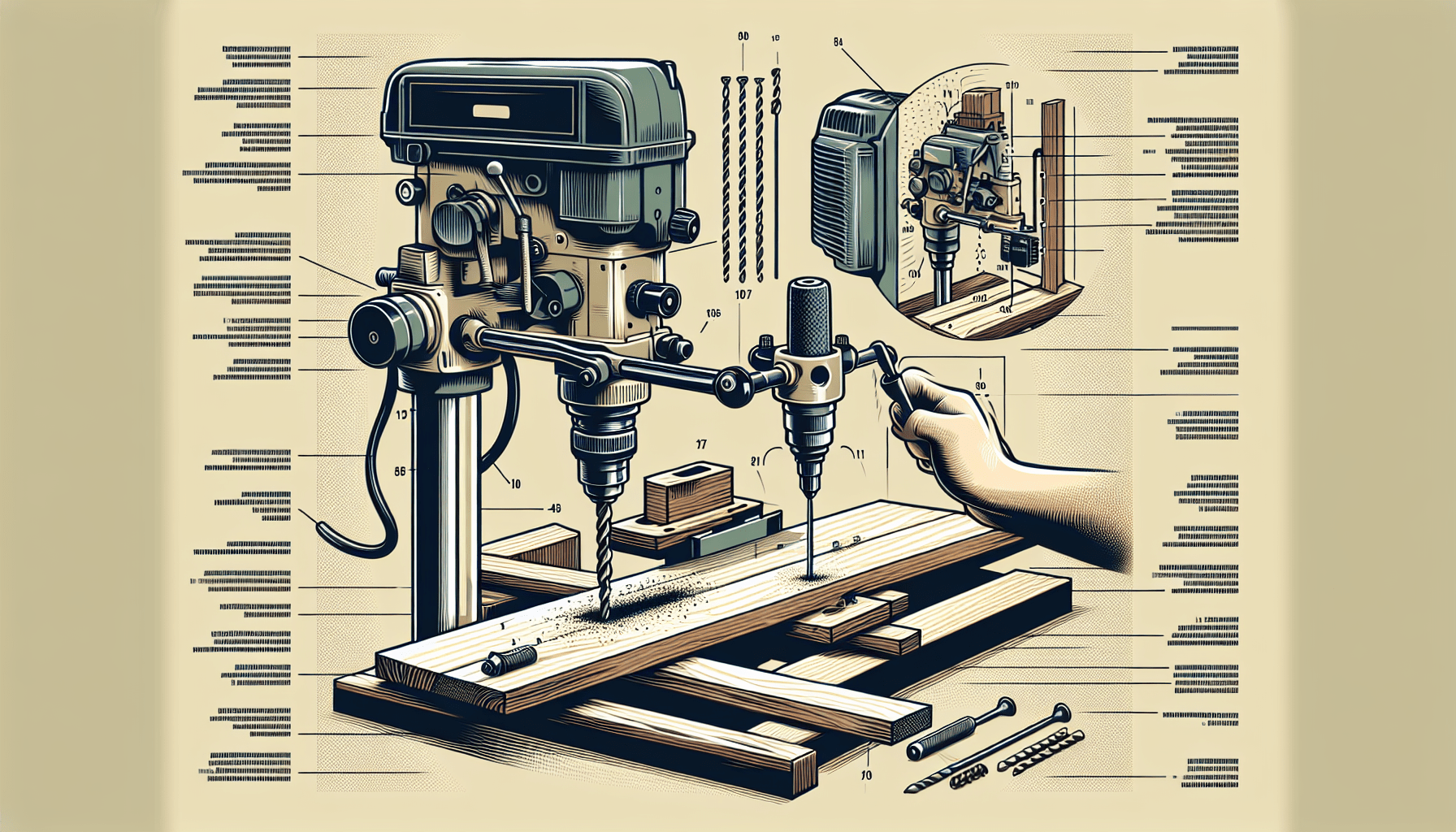

Setting Up and Operating the Drill

Proper setup and operation of the column drill are vital for achieving accurate and safe drilling.

Assembling the Drill

Before using the column drill, it is important to carefully follow the manufacturer’s instructions and assemble all necessary components. These may include attaching the drill head to the column, installing the table, and securing any additional accessories.

Adjusting the Table Height

Adjusting the table height is essential for comfort and precision. The table should be set at a level that allows easy access to the workpiece and provides a stable platform for drilling. Adjustments can be made using the height adjustment mechanism present in most column drills.

Securing the Workpiece

To ensure stability and prevent the workpiece from moving, it is important to secure it using clamps or other appropriate methods. This reduces the risk of accidents and helps in achieving accurate drilling results.

Operating the Drill

When operating the column drill, it is important to maintain a firm grip on the feed handle and apply gentle and consistent pressure. Start the drill at a slow speed and gradually increase it to the desired level. Always be aware of the position of your hands and fingers in relation to the rotating drill bit.

Maintenance and Care

Regular maintenance and proper care are crucial for keeping the column drill in optimal condition.

Cleaning and Lubrication

Clean the drill regularly by removing any dust, debris, or residue that may accumulate on the drill body, spindle, and chuck. Lubricate moving parts and apply grease or oil as recommended by the manufacturer. This helps to reduce friction, prevent rust, and prolong the lifespan of the drill.

Replacing Worn Parts

Inspect the column drill for any worn or damaged parts regularly. Replace any parts that show signs of wear, such as belts, chuck keys, or safety guards. This ensures safe and efficient operation and prevents potential accidents or damage to the drill.

Checking Belt Tension

The belt that drives the drill’s rotational power should be checked periodically to ensure proper tension. Loose or slipping belts can affect the performance and accuracy of the drill. Adjust the belt tension as necessary, following the manufacturer’s guidelines.

Common Applications

Column drills are versatile tools that find applications in various industries and projects.

Woodworking Projects

Column drills are commonly used in woodworking projects such as furniture making, cabinetry, and joinery. They provide accurate and clean holes for doweling, drilling for hardware installation, and other woodworking tasks.

Metalworking Tasks

In metalworking, column drills are used for drilling holes in metal sheets, tubes, or bars. They are essential in metal fabrication, automotive repair, and other metal-related industries. The precision and control provided by column drills ensure accurate and consistent results.

Construction and DIY Projects

Column drills are valuable tools in construction and do-it-yourself (DIY) projects. They are used for tasks such as drilling holes for wiring, plumbing, or mounting fixtures. The ability to adjust the drilling depth and control the speed makes column drills suitable for a wide range of construction applications.

Tips and Tricks

Here are some tips and tricks to enhance your drilling experience with a column drill:

Using Clamps for Stability

When drilling smaller or irregularly shaped workpieces, securely clamp them to the drill table or a workbench. This provides stability and prevents the workpiece from moving during drilling.

Start with a Pilot Hole

For drilling large or deep holes, it is advisable to start with a smaller pilot hole. This helps guide the larger drill bit, reduces the risk of the bit wandering off course, and provides a cleaner and more precise hole.

Drilling at Appropriate Speeds

Different materials require different drilling speeds. Consult the manufacturer’s recommendations or refer to drilling speed charts to determine the appropriate speed for the material you are working with. Using the wrong speed can lead to overheating, reduced bit life, or poor quality holes.

In conclusion, a column drill is a powerful and versatile tool that offers precision and control for drilling operations. Understanding the components, features, and proper usage of a column drill is crucial for achieving safe and accurate results. By following the tips and tricks outlined in this article, you can enhance your drilling experience and ensure the longevity of your column drill.