In the world of power tools, there are numerous options to choose from, each with its own unique features and functions. Two such options include the vertical drill and the column drill. While they may seem similar at first glance, there are fundamental differences between the two that make them suitable for various tasks. In this article, we will explore and clarify the distinctions between a vertical drill and a column drill, helping you to understand which one is best suited for your specific needs.

Definition of a vertical drill

A vertical drill, also known as a bench drill, is a power tool used for drilling holes in various materials. It is designed to be mounted on a workbench or table and is commonly used in workshops, garages, or small-scale manufacturing settings. With a vertical drill, you can easily drill precise and accurate holes with control and stability.

Explanation of a vertical drill

A vertical drill consists of a motor, a drilling spindle, and a worktable. The motor provides the necessary power to rotate the drilling spindle, which holds the drill bit and carries out the drilling action. The worktable can be adjusted vertically to accommodate different workpiece heights. This feature allows for versatility and flexibility in drilling various sizes of holes.

Features of a vertical drill

Vertical drills typically come with several features to enhance their functionality. Some common features include adjustable drill speed, depth control mechanism, and a chuck system for securely holding different sizes of drill bits. Additionally, vertical drills may incorporate safety features such as a protective guard and a emergency stop button to ensure the user’s safety during operation.

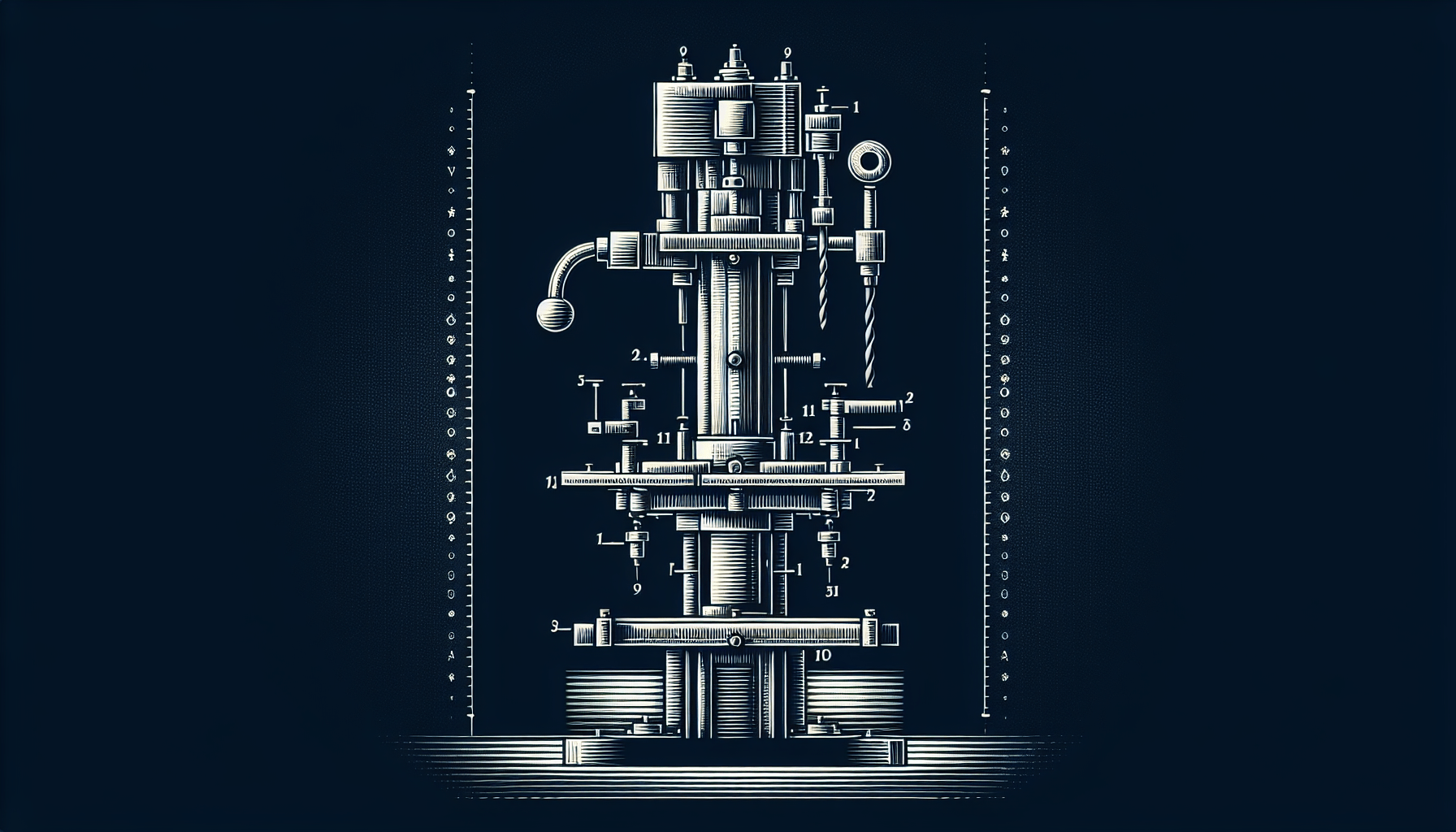

Definition of a column drill

A column drill, also referred to as a floor drill press, is a larger and more powerful drilling machine used for heavy-duty drilling tasks. It is commonly found in industrial settings, construction sites, and professional workshops. A column drill offers increased stability, precision, and drilling capacity compared to a vertical drill.

Explanation of a column drill

A column drill consists of a sturdy upright column that supports the drilling head, which houses the motor, spindle, and other components. The drilling head is adjustable in height and can be moved along the column to accommodate different workpiece sizes. Column drills are known for their larger drilling capacity and ability to handle more demanding drilling projects.

Features of a column drill

Column drills are equipped with several features that make them ideal for heavy-duty drilling tasks. These features may include a powerful motor with multiple speed options, a larger worktable with adjustable angles for versatile drilling positions, and a robust chuck system that can securely hold large-sized drill bits. Additionally, column drills often have a built-in laser guide or depth stop mechanism for better drilling precision.

Structural Differences

Vertical alignment of a vertical drill

One of the main structural differences between a vertical drill and a column drill is the alignment of their drilling apparatus. In a vertical drill, the drilling spindle is mounted vertically, perpendicular to the worktable. This arrangement allows for precise drilling actions straight down into the workpiece. The vertical alignment of the drilling spindle ensures stability and accuracy during the drilling process.

Upward movement and positioning of a column drill

On the other hand, a column drill features an adjustable drilling head that can be raised or lowered along the column. This upward movement enables the column drill to accommodate larger and taller workpieces. The ability to position the drilling head at different heights provides greater flexibility in drilling holes at various depths and positions, making it suitable for a wider range of applications.

Working Principle

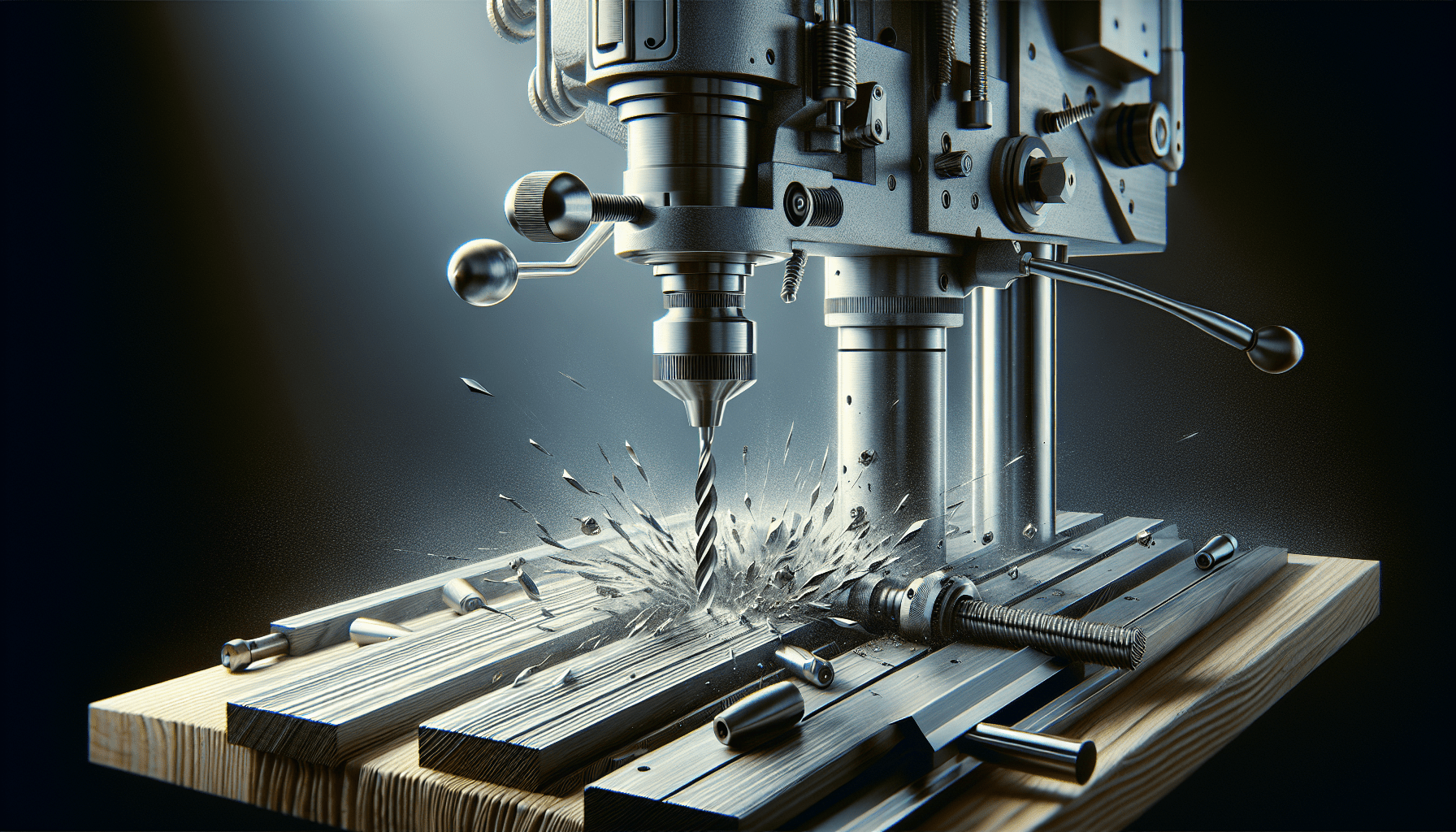

Drilling direction of a vertical drill

The working principle of a vertical drill is straightforward. When the motor is turned on, it drives the drilling spindle to rotate, causing the drill bit attached to it to drill into the workpiece. Due to the vertical alignment of the spindle, the drilling action is directly downward, resulting in holes that are perpendicular to the worktable. This allows for precise and accurate drilling in a controlled manner.

Motion and drilling capabilities of a column drill

A column drill operates on a similar principle but with additional motion capabilities. The drilling head of a column drill can be raised or lowered along the column, enabling the user to drill at different heights and depths. This vertical motion, combined with the rotational movement of the drilling spindle, allows for more versatile drilling actions. Column drills often offer higher drilling capacities and can handle larger workpieces with ease.

Application Areas

Typical uses of a vertical drill

A vertical drill is commonly used in woodworking, metalworking, and DIY projects. It is suitable for drilling small to medium-sized holes in materials such as wood, metal, plastics, and composites. With its precision and stability, a vertical drill is an essential tool for tasks such as furniture making, cabinetry, model building, and general drilling applications where accuracy is crucial.

Specific tasks suitable for a column drill

A column drill is designed to handle larger and more demanding drilling tasks. It finds immense utility in industrial settings, construction sites, and professional workshops. Column drills are ideal for heavy-duty drilling projects that involve drilling into thick metal, concrete, and other tough materials. They are commonly used for metal fabrication, mechanical engineering, drilling holes for pipes, and other applications where high drilling capacities and precision are required.

Size and Dimensions

Compactness of a vertical drill

Vertical drills are generally more compact and portable compared to column drills. They are designed to be used on a workbench or table, occupying relatively small space in a workshop. The compact size of a vertical drill makes it easier to transport and store, making it a suitable choice for those with limited space or who require mobility.

Larger size and stability of a column drill

Column drills, on the other hand, are larger and bulkier machines. Due to their heavy-duty nature and the need for stability, they are constructed with larger frames and sturdy bases. The increased size and weight of a column drill provide enhanced stability during operation, reducing vibrations and ensuring precision drilling even at higher speeds. The larger dimensions of a column drill also contribute to its greater drilling capacity and ability to handle larger workpieces.

Manufacturers and Brands

Prominent manufacturers of vertical drills

Some well-known manufacturers of vertical drills include Bosch, DeWalt, Makita, and Craftsman. These companies have a reputation for producing high-quality power tools, including vertical drills, that are reliable, durable, and perform well in various drilling applications. When considering a vertical drill, it is advisable to choose a reputable manufacturer to ensure the tool’s longevity and performance.

Renowned brands for column drills

For column drills, there are several renowned brands that specialize in manufacturing heavy-duty drilling machines. Brands such as Jet, Delta, WEN, and Powermatic are known for their excellent craftsmanship, durability, and reliable performance. These brands offer a wide range of column drills with varying specifications and features to cater to the diverse needs of professionals and industrial users.

Price Range

Cost variations for vertical drills

The price of a vertical drill can vary depending on factors such as brand, features, and quality. Basic models suitable for DIY enthusiasts and hobbyists can range from $50 to $200. Mid-range vertical drills with more advanced features and better build quality can be found in the $200 to $500 range. Professional-grade vertical drills, designed for heavy-duty use, can cost upwards of $500 or more.

Price range for column drills

Column drills, being larger and more powerful machines, generally come with a higher price tag compared to vertical drills. Entry-level column drills suitable for light to medium-duty tasks can range from $200 to $500. Mid-range column drills with better drilling capacities, adjustable features, and higher-quality components can be found in the $500 to $1500 range. Industrial-grade column drills, offering top-notch performance and features, can cost several thousand dollars.

Advantages and Disadvantages

Benefits of using a vertical drill

- Precise drilling: A vertical drill allows for accurate drilling in a controlled manner, making it perfect for tasks that require precision.

- Compact and portable: The compact size of a vertical drill makes it easy to transport, store, and use in various spaces.

- Versatile: Vertical drills can handle a wide range of materials and hole sizes, making them suitable for multiple applications.

- Affordable: Vertical drills are generally more budget-friendly compared to larger column drills, making them accessible to a wider range of users.

Pros and cons of using a column drill

- Increased drilling capacity: Column drills can handle larger workpieces and offer higher drilling capacities, making them suitable for heavy-duty applications.

- Enhanced stability: The larger size and sturdy construction of a column drill provide increased stability, reducing vibrations and ensuring precise drilling.

- Expensive and bulky: Column drills come with a higher price tag and occupy more space in a workshop, making them less accessible for casual users or those with limited space.

- Overkill for simple tasks: While column drills excel in heavy-duty drilling, they may be unnecessary for simpler drilling tasks that can be accomplished with a vertical drill.

Choosing the Right Drill

Considerations for selecting a vertical drill

When choosing a vertical drill, it is essential to consider factors such as:

- Power and speed options: Ensure that the vertical drill has sufficient power and variable speed options to match the drilling requirements of your projects.

- Chuck system: Look for a vertical drill with a versatile chuck system that can hold various sizes of drill bits securely.

- Adjustability and stability: Check if the worktable is adjustable in height, allowing for flexibility in drilling different-sized workpieces. Also, consider the stability of the drill during operation.

- Safety features: Look for safety features such as a protective guard, emergency stop button, and overheating protection to ensure safe use.

Factors to consider when choosing a column drill

When selecting a column drill, take into account the following factors:

- Drilling capacity: Consider the maximum drilling capacity of the column drill to ensure it can handle the size of your workpieces.

- Adjustability and versatility: Look for a column drill with adjustable drilling angles and a movable drilling head to accommodate various drilling positions.

- Motor power and speed options: Ensure that the column drill has a powerful motor and multiple speed options to tackle different drilling applications.

- Build quality and durability: Consider the overall build quality and durability of the column drill, especially if you require it for heavy-duty or industrial use.

In conclusion, the difference between a vertical drill and a column drill lies in their structural design, drilling capabilities, and intended applications. A vertical drill is compact, portable, and suitable for woodworking, metalworking, and DIY projects, offering precision and versatility. On the other hand, a column drill is larger, more powerful, and built for heavy-duty drilling tasks in industrial and professional settings. When selecting a drill, consider your specific needs, budget limitations, and the intended applications to choose the right drill that meets your requirements.