If you’re curious about what a taladro de columna is, then this article will provide you with a brief overview. Known as a column drill in English, a taladro de columna is a specialized tool used for drilling precise holes in various materials. It consists of a vertical column that supports a motorized drill head, which can be adjusted in height and angle to accommodate different drilling needs. Whether you’re a DIY enthusiast or a professional tradesperson, understanding the basics of a taladro de columna can enhance your drilling capabilities and make your projects more efficient.

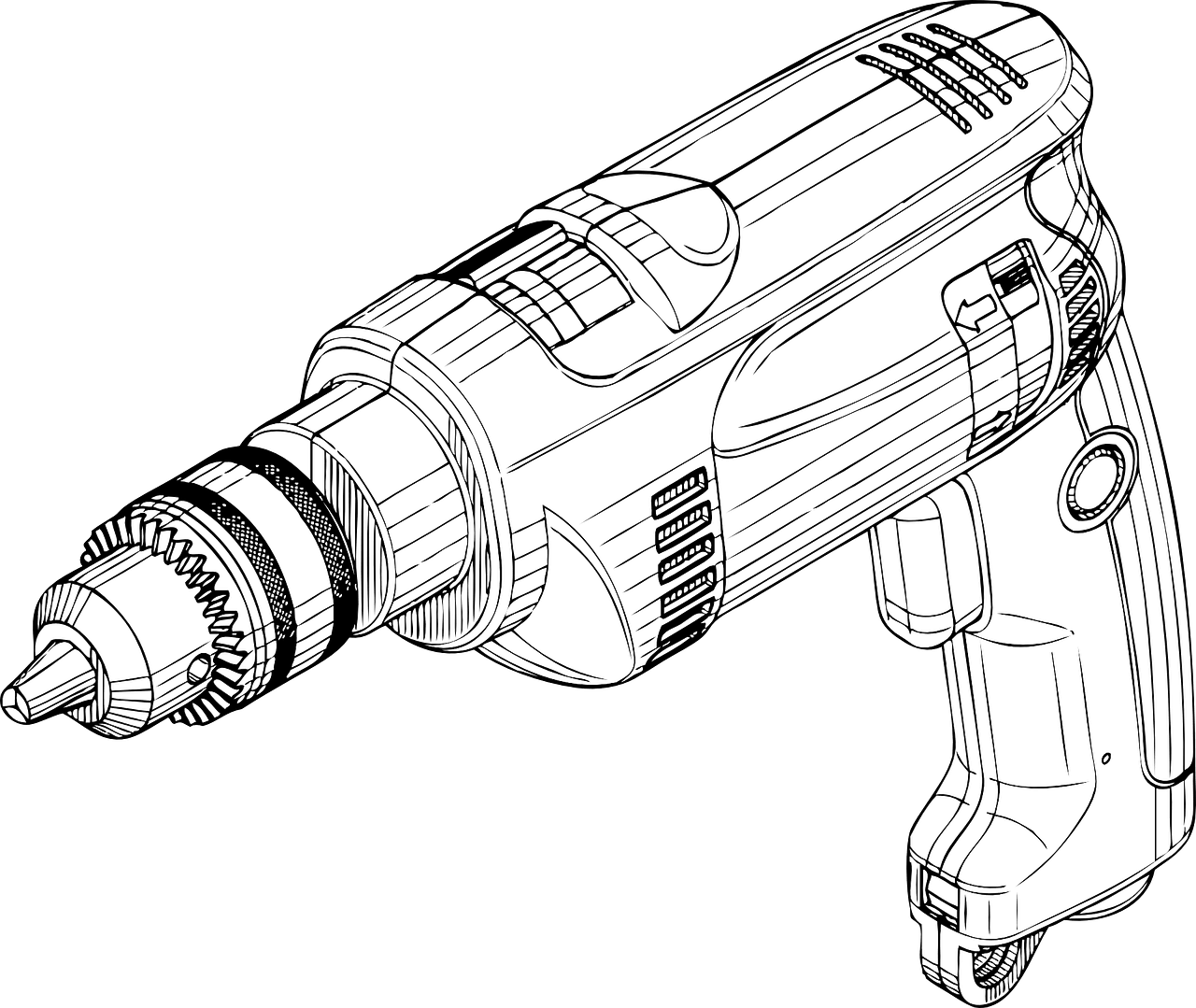

Definition of Drill Press

A drill press, also known as a drilling machine or pillar drill, is a tool used for drilling holes in various materials such as wood, metal, masonry, and plastic. It consists of a powerful motor, a stable column or pillar, and a vertically adjustable spindle. The spindle holds the drill bit and can be lowered or raised to control the depth of the hole. The drill press is typically mounted on a sturdy base or workbench, providing stability and precise drilling capabilities.

Types of Drill Press

Benchtop drill press

The benchtop drill press is a compact and portable version of the drill press. It is designed to be mounted on a workbench or table and is ideal for small to medium-sized projects. The benchtop drill press offers versatility and ease of use, making it a popular choice for hobbyists, DIY enthusiasts, and small workshops.

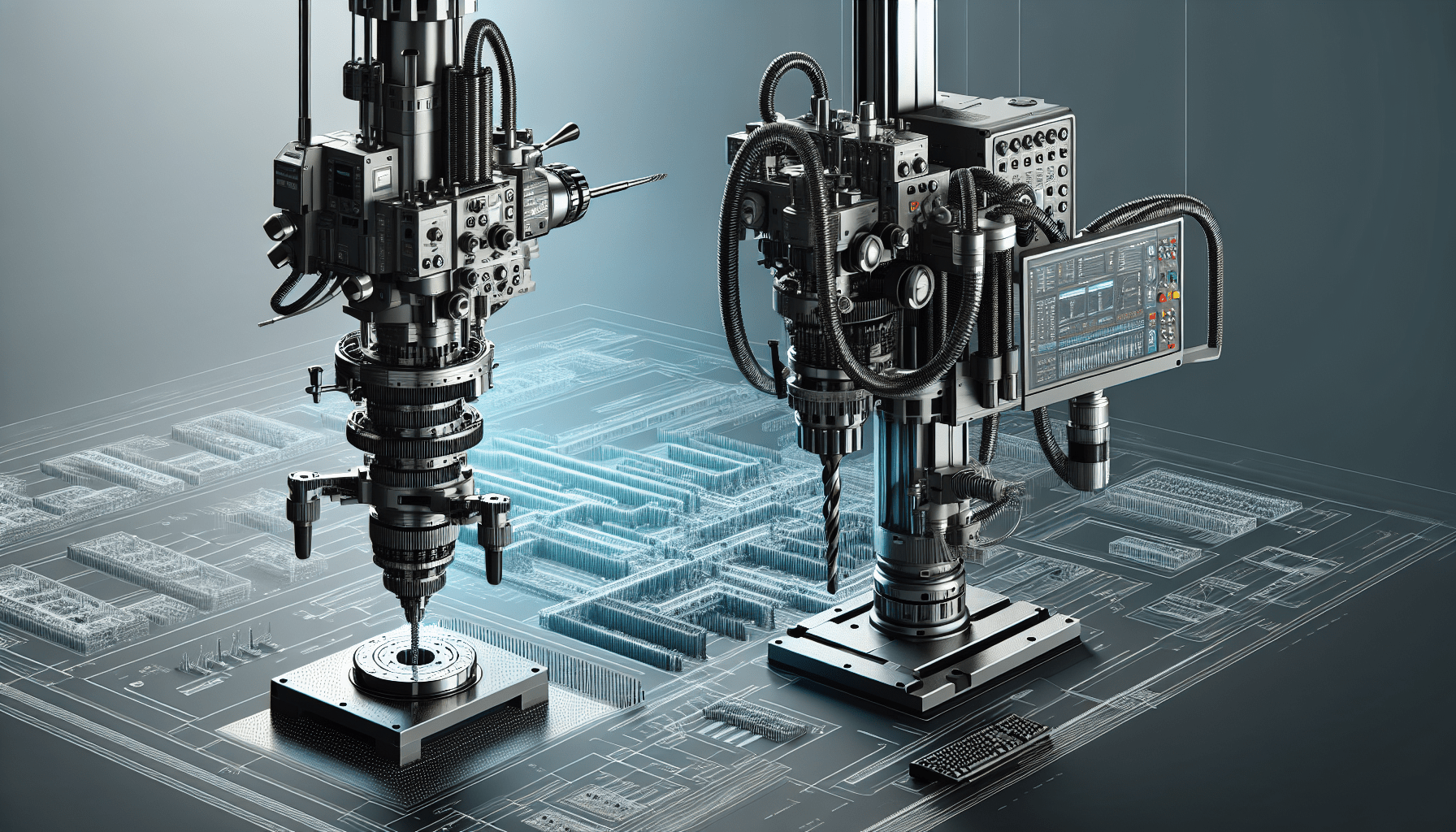

Floor drill press

The floor drill press, as the name suggests, is a larger and more robust version of the drill press. It is designed to be placed directly on the floor and is suitable for heavy-duty drilling tasks. The floor drill press often comes with a wider range of speed options and larger drilling capacity, making it ideal for professional workshops and industrial applications.

Magnetic drill press

The magnetic drill press is a specialized type of drill press used mainly in metalworking industries. It features a magnetic base that securely attaches to the workpiece, providing stability and precision during drilling. The magnetic drill press is commonly used for drilling holes in large metal structures such as steel beams and pipes.

Features and Functions

Variable speed control

One of the key features of a drill press is its variable speed control. This allows you to adjust the speed of the spindle according to the material being drilled and the size of the drill bit. Different materials and drill bit sizes require different RPM (rotations per minute) settings to achieve optimal drilling results. Having variable speed control makes it easier to tackle a wide range of projects.

Depth stop

The depth stop is a function that allows you to set the desired drilling depth. It ensures that the drill bit does not go beyond a certain point, resulting in consistent and accurate hole depths. The depth stop is particularly useful when you need to drill multiple holes at the same depth.

Table tilting

Many drill presses come with a tilting table that can be adjusted to different angles, allowing you to drill holes at various angles or create angled cuts. This feature adds versatility to your drilling capabilities and enables you to work on more complex projects.

Quill travel

The quill travel refers to the vertical movement of the spindle or quill. It determines the maximum depth of the hole that can be drilled. A drill press with a larger quill travel offers greater drilling capacity and versatility, allowing you to drill deep holes when needed.

Drilling capacity

The drilling capacity of a drill press is the maximum diameter of the hole that can be drilled. It depends on the distance between the center of the spindle and the column, commonly referred to as the throat distance. A larger drilling capacity means that you can work with larger drill bits and drill holes of greater diameter.

Chuck size

The chuck size refers to the diameter of the drill bit that can be securely held in the drill press. A larger chuck size allows you to use a wider range of drill bit sizes, providing more flexibility in your drilling tasks.

Spindle travel

The spindle travel refers to the distance that the spindle can be lowered or raised. It determines the maximum depth of the hole that can be drilled. A drill press with a longer spindle travel allows you to drill deeper holes.

Motor power

The motor power of a drill press determines its drilling performance. Higher motor power provides more torque and allows you to drill through tougher materials with ease. When considering motor power, it is important to match it with the type of projects you will be working on.

Accuracy and precision

One of the main advantages of using a drill press is its ability to provide precise and accurate drilling. The combination of stable construction, adjustable depth settings, and secure workpiece clamping ensures consistent results. The precision of a drill press is crucial, especially when drilling holes that need to be aligned accurately or when working on intricate projects.

Advantages of Using a Drill Press

Increased stability and accuracy

One of the major advantages of using a drill press is the increased stability it offers compared to handheld drills. The solid construction and the ability to mount the drill press on a workbench provide a stable platform, minimizing the risk of errors and ensuring accurate drilling.

Suitable for repetitive drilling tasks

When it comes to repetitive drilling tasks, a drill press is a game-changer. It allows you to adjust depth settings, secure the workpiece, and drill multiple holes with consistent accuracy. This makes it ideal for tasks such as creating dowel joints, drilling holes for hardware installation, or making evenly spaced holes for shelving.

Versatility in drilling materials

Whether you’re working with wood, metal, plastic, or masonry, a drill press can handle a wide range of materials. By selecting the appropriate drill bits and adjusting the speed settings, you can achieve clean and precise holes in different materials.

Option to use specialty drill bits

A drill press opens up the possibility of using specialty drill bits that are designed for specific tasks. For example, you can use Forstner bits for clean and flat-bottomed holes in woodworking, or step drill bits for enlarging existing holes. The ability to use specialty drill bits enhances the versatility of a drill press.

Safer operation compared to handheld drills

Operating a drill press is generally considered safer than using handheld drills. The stability of the drill press reduces the risk of the drill bit slipping or the workpiece moving during drilling. Additionally, many drill presses come with safety features such as protective shields, emergency stop buttons, and a built-in depth stop for added safety.

Common Applications

Woodworking

One of the most common applications of a drill press is in woodworking. Whether you’re building furniture, constructing cabinets, or creating intricate woodcrafts, a drill press can make precise and clean holes for dowels, screws, and hardware. Woodworkers often rely on drill presses for tasks such as drilling pocket holes, creating mortises, and countersinking.

Metalworking

In metalworking, a drill press is essential for drilling holes in metal sheets, profiles, and pipes. The stability and power of a drill press are crucial when working with tough and hard metals. It allows for precise alignment of holes for fasteners, creating threaded holes, and drilling large diameter holes in metalwork.

Masonry

Drill presses equipped with specialty masonry drill bits can drill holes in brick, concrete, and other masonry materials. This makes them useful for tasks such as installing anchors, creating holes for pipes and cables, or building structures with masonry components.

Automotive

In the automotive industry, drill presses are commonly used for tasks such as drilling holes for bodywork repairs, installing brackets or fasteners, and creating holes in metal components. The precision and power of a drill press are valuable when working with the various materials found in automotive applications.

Electronics

Drill presses are also used in electronics for drilling holes in circuit boards, enclosure boxes, and other electronic components. They offer the accuracy and control needed for creating clean and precise holes without damaging delicate electronic parts.

Hobby projects

Whether you’re a DIY enthusiast or a dedicated hobbyist, a drill press can be a valuable tool for various projects. From jewelry making to model building, a drill press can help you achieve accurate drilling in different materials, providing a solid foundation for your creative endeavors.

How to Safely Use a Drill Press

Wearing appropriate safety gear

When operating a drill press, it is essential to wear appropriate safety gear. This includes safety goggles or face shield to protect your eyes from flying debris, ear protection to reduce noise levels, and non-slip gloves to ensure a firm grip on the workpiece.

Securing the workpiece

Before drilling, ensure that the workpiece is securely clamped to the drill press table or vice. This prevents the workpiece from moving during drilling, reducing the risk of injury and ensuring accuracy.

Adjusting speed and depth settings

Choose the appropriate speed setting for the material and drill bit being used. Slower speeds are usually recommended for drilling through metal, while higher speeds are suitable for wood and plastic. Additionally, adjust the depth stop to control the drilling depth, ensuring that the drill bit does not go beyond the desired point.

Using the correct drill bits

Using the correct drill bits for the material being drilled is crucial for achieving clean and accurate holes. Different materials require specific drill bit types and designs. Ensure that the drill bit is securely tightened in the chuck before drilling.

Avoiding excessive force

Let the drill bit do the work and avoid applying excessive force. Applying too much pressure can cause the drill bit to break or the workpiece to move unexpectedly, increasing the risk of injury. Apply a steady and consistent pressure, allowing the drill bit to cut through the material smoothly.

Practicing good housekeeping

Keep the work area clean and free from debris. Remove any chips or scrap material from the drill press table after each drilling operation. This helps maintain a safe and clutter-free work environment, reducing the risk of accidents.

Maintenance and Care

Regular cleaning and lubrication

To keep your drill press in optimal condition, it is important to regularly clean it and lubricate any moving parts. Wipe down the surfaces with a clean cloth and remove any dust or debris. Lubricate the spindle, gears, and other movable parts according to the manufacturer’s recommendations.

Checking for wear and tear

Inspect your drill press regularly for any signs of wear and tear. Look for loose or damaged parts, worn-out belts, or any abnormalities in the functioning of the drill press. Promptly repair or replace any worn-out components to ensure safe and accurate operation.

Replacing worn-out parts

Over time, certain parts of the drill press, such as belts and drill bits, may wear out and need replacement. Follow the manufacturer’s instructions for replacing these parts to maintain optimal performance and safety.

Ensuring proper electrical connections

If your drill press is powered by electricity, ensure that the electrical connections are secure and in good condition. Check the power cord for any damage and make sure the plug is properly grounded. Faulty electrical connections can pose a safety risk and should be addressed immediately.

Storing in a dry and clean environment

When not in use, store your drill press in a dry and clean environment to prevent corrosion and damage. If possible, cover it to protect it from dust and moisture. Proper storage helps prolong the lifespan of your drill press and ensures it is ready for use when needed.

Popular Drill Press Brands

Makita

Makita is a well-known brand in the power tool industry, offering a wide range of high-quality drill presses for various applications. Their drill presses are known for their reliability, durability, and precision.

WEN

WEN is another popular brand that specializes in drill presses and other power tools. They offer a range of drill presses suited for both professional and DIY use. WEN drill presses are known for their affordability and user-friendly features.

JET

JET is a trusted brand in the woodworking and metalworking industries. Their drill presses are known for their robust construction, precision, and versatility. JET drill presses are often favored by professionals for their superior quality and performance.

DEWALT

DEWALT is a renowned brand in the power tool market, known for producing high-performance tools. Their drill presses combine power, durability, and precision, making them a popular choice among professionals and enthusiasts alike.

Craftsman

Craftsman has been a household name in the tool industry for decades. They offer a range of drill presses suitable for various applications. Craftsman drill presses are known for their solid build quality and reliable performance.

SKIL

SKIL is a brand that focuses on providing affordable yet reliable power tools, including drill presses. Their drill presses offer a good balance between performance and affordability, making them suitable for DIY projects and hobbyist use.

Factors to Consider when Buying a Drill Press

Type of projects

Consider the type of projects you will be working on to determine the size and capabilities required in a drill press. Smaller benchtop drill presses are suitable for light to medium-duty tasks, while larger floor drill presses are better suited for heavy-duty applications.

Power and speed requirements

Evaluate the power and speed requirements based on the materials and drill bit sizes you will be working with. Ensure that the drill press you choose has sufficient motor power and variable speed settings to meet your specific needs.

Budget

Set a budget for your drill press purchase and look for options within that range. Consider any additional accessories or features you may need and factor in their costs as well.

Available space for installation

Determine the available space in your workshop or garage for installing a drill press. Measure the dimensions of the drill press and make sure it fits comfortably in the designated area.

Durability and reliability

Look for a drill press that is built to last and can withstand heavy usage. Check customer reviews and ratings to gauge the durability and reliability of different models.

Additional features

Consider any additional features that may enhance the usability and convenience of the drill press. This can include features such as LED work lights, laser guides, digital displays, or built-in dust collection systems.

Conclusion

In conclusion, a drill press is a versatile and essential tool for a wide range of drilling tasks. From woodworking to metalworking, this tool offers stability, accuracy, and precision that handheld drills cannot match. Whether you’re a professional craftsman or a hobbyist, choosing the right drill press can greatly enhance your productivity and the quality of your work. Consider your specific drilling needs, safety requirements, and budget when selecting a drill press that meets your requirements. With the right drill press by your side, you can tackle any drilling project with confidence and ease.